Wire rope has been used for over a hundred years in the mining industry. The first wire rope was invented by a German engineer and was found to be much better than hemp rope or chain. This early wire rope was made of three larger strands woven together, each of which contained four individual wires. In the nineteenth century, wire rope was used in a variety of industries, including cable cars and lines for mine shafts. Wire rope suppliers included John A. Roebling, who became famous for successfully building suspension bridges.

Today, wire rope is made from steel wires woven together in a particular fashion, either forming stranded rope or spiral rope. Usually, the wires are made of carbon steel. Wire rope suppliers classify ropes according to the different uses that they fulfill. Running ropes are generally stranded, and are bent over different structures to support weight. Most of the stress placed on them is bending stress, rather than tensile stress. Stationary ropes are usually spiral wound, and mainly operate under tension. Track ropes are used, as the name would suggest, as tracks for pulleys and rollers. Lastly, wire rope slings can be used to harness down or lift goods in various fashions. Like running ropes, they are mostly under bending stress when bending around the edges of objects. It is important to know exactly what conditions your wire rope needs to fulfill before purchasing rope for any project.

Looking for a Melbourne wire rope supplier? A. Noble & Son has been servicing the industry for years with high quality lifting and hoisting equipment.

Showing posts with label industry. Show all posts

Showing posts with label industry. Show all posts

Friday, January 31, 2014

Saturday, September 28, 2013

Do’s and don’ts while using lifting beams

|

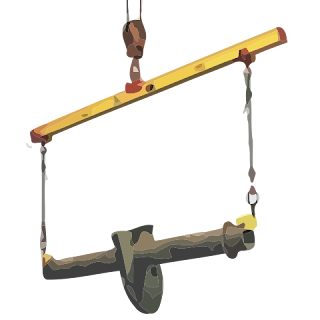

| A lifting beam in action |

While calculating the total load which will be imposed on the crane hook, the weight of the beam and its attachments must be added to the weight of the load. Make certain that the SWL on the individual lift points remain within the limits and be sure to take extra care where these are adjustable.

The load should be stable so that the beam remains at its intended attitude during use. Take extra care while lifting and setting down the load as at these points the risk of instability and overload is maximum.

Lifting beams require minimal maintenance but there are certainly some things to take care of. Make sure the bolted joints are in good shape and corrosion damage is prevented. Regularly inspection of lifting beams is very important in order to prevent any accident.

Labels:

industrial,

industry,

lift,

lifting,

lifting beams,

rigging

Subscribe to:

Posts (Atom)