Fibre ropes can be used for many purposes including tying an object together securely without causing too much pressure on an object.

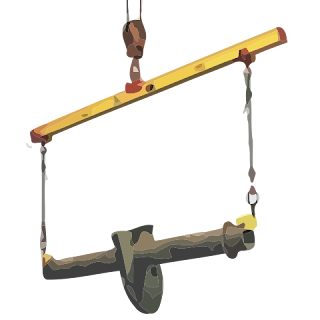

These types of rope can also be securely weave through or tied onto a crane or pulley system as a part of the mechanism to lift heavy objects from one area to another.

What types of fibre ropes can a rigger use to perform their tasks?

- Double Braid Polyester

- Ice Blue

- Nylon

- Polyethylene

- Superdan

- Superflex

- Supermax plus

- Supermax

Depending on the type of task being performed by a rigger, a fibre rope is the better option over a wire rope for many factors including:

- Flexibility – Fibres are more flexible to bend or wrap around object better than wire ropes for certain objects.

- Strength – a fibre rope can be strong as it is tightly bound together using multiple fibre strands to increase its strength

- Sizes – the length of some wire ropes may not be long enough to suit the task, therefore require a fibre rope that may be longer in size.

- Weight options – the lightweight material would be ideal if you don’t want to add weight to the object your carrying but can be still securely hold the object.

- Compact – with the fine fibres it can be wound up tight and be easier to store in confined spaces