|

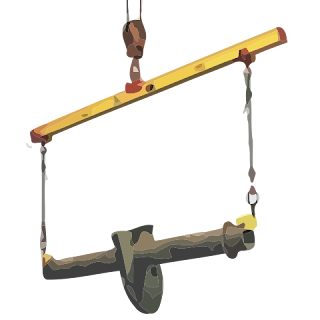

| A lifting beam in action |

While calculating the total load which will be imposed on the crane hook, the weight of the beam and its attachments must be added to the weight of the load. Make certain that the SWL on the individual lift points remain within the limits and be sure to take extra care where these are adjustable.

The load should be stable so that the beam remains at its intended attitude during use. Take extra care while lifting and setting down the load as at these points the risk of instability and overload is maximum.

Lifting beams require minimal maintenance but there are certainly some things to take care of. Make sure the bolted joints are in good shape and corrosion damage is prevented. Regularly inspection of lifting beams is very important in order to prevent any accident.